Changying Hainan Eco-Cultural Industrial Park Project German District Project

Changying Hainan Eco-Cultural Industrial Park Project German Zone Project is located in Changliu, Xiuying District, Haikou City, Haikou City. Under the premise of meeting the requirements of the architectural plan, the appearance of the building highlights the shape of the Alpine snow mountain, and uses a moderately friendly modern architectural language to create an overall image of the German snow mountain. It is composed of 9 buildings and presents the effect of a snow mountain, highlighting the key points , The space is rich in three-dimensional layers. The three-dimensional modeling increases the virtual and real changes of the building, and emphasizes the artistic perception of the building, as if it has come to the snow-capped Alps. The roof adopts light steel keel and 2.5mm aluminum plate surface sprayed with the effect of a piece of snow. The snow-white mountains add to the elaboration of the building and the natural beauty. The contrast between the virtual and the reality and the uneven change make the building richer and more upright. To nature, the snow-capped mountains seem to be by our side.

Total surface area:18205㎡。

Building podium: It is composed of 9 buildings, each with a height of 17.55-57.23 meters.

The structural systems of the 1#~9# buildings of this project all adopt a steel frame-steel supporting structure system.

The roof model structure adopts the frame column adopts round tube column; the frame beam adopts rectangular tube steel beam; the support adopts round tube support, the roof adopts light steel keel and 2.5mm thick aluminum plate, and the aluminum plate is sprayed with snowflake effect, which should achieve the effect of Alpine snow.

Roof decoration steel frame part, there are 9 floors in 1#~9# building, the highest elevation of each structure top is (1#-9#) 57.23m, 31.31m, 24.36m, 20.91m, 17.55m, 19.25m , 33.61m, 26.02m, 19.14m, the structural system adopts steel frame-steel support system, the column adopts round tube column, and the beam adopts rectangular tube steel beam.

Building function and floor height

Serial number

Floor number

Floor

Highest point

Use function

Construction area

1

1#Brothers Grimm and Chocolate Experience Zone

4th floor

57.23m

business

4846.8㎡

2

2#public toilet

2层

31.37m

Public toilets, logistics

459.8㎡

3

3#Swiss watch experience area

3 floors

24.36m

business

1133.8㎡

4

4#Laser Cinema Experience Zone

1 floor

20.91m

entertainment

1701.0㎡

5

5#German Car Experience Center

2 floors

17.55m

business

1073.4㎡

6

6#Public restroom 2

1 floor

19.25m

Public toilet

266.2㎡

7

7#Soaring Europe

2 floors

33.61m

entertainment

3130.1㎡

8

8#Oktoberfest experience area

2 floors

26.02m

food

3997.8㎡

9

9#Oktoberfest experience area

2 floors

19.14m

food

1465.6㎡

Project name: Changying Hainan Ecological and Cultural Industrial Park Project German District

Project Manager: Xie Bibo/Pan Longbao Designer: Shen Bo

Pre-settlement officer: Chen Liren Quality safety officer: Li Jie

Construction worker: Wang Jinjian Team: Baobao Lei

2020-06-08 15:11

MORE

Construction of the commercial center and light industrial plant in the Kigali Special Economic Zone

1. Project name: Construction of the commercial center and light industrial plant in the Kigali Special Economic Zone

2. Project location:Gasabo Bumbogo Kinyaga Akakaza

3. Construction unit:PEZ LTD COMMERCIAL CENTER

4. Consulting unit:PRISMA

5. Contract amount:13,824,821,866 FRW

6. Project introduction:

This project is the construction of a commercial center and a light industrial plant in the Kigali Special Economic Zone. It covers an area of 50,000 m2. It is a large-scale commercial center integrating commercial buildings and warehouses, as well as civil engineering, steel structure, and curtain wall engineering. The construction projects mainly include the structure and decoration of the commercial center building, the structure and decoration of the two commercial warehouses, the outdoor road and parking lot engineering, the outer wall and retaining wall engineering, the outdoor greening engineering, fire protection and water and electricity engineering.

This project is one of the projects with larger area and higher contract value received by our company in Rwanda. The commercial center building is a five-block conjoined building with a construction area of 10,000 m2; warehouses No. 1 and No. 2 each have a construction area of 2,700 m2. The highest height of the commercial center building is 22.57m, the height of No. 1 and 2 workshops is 6.99m, and the largest span is 18m.

At present, all construction links of this project have become formal, and the sub-item construction on site has been recognized and praised by the consulting unit.

9. Project organization:

1. Project Manager: Jiang Huijun 2. Production Manager: Yang Yuai

3. Designer: Yang Hui 4. Quality safety officer: Yin Jitao

5. Pre-settlement clerk: Wang Wenchao 6. Construction foreman: Zhu Jiang, Chen Hongfei

2020-06-08 15:08

MORE

Steel Structure Project of Building A of Commercial and Residential Building in Haikou "Harmonious Home"

The steel structure project of Building A of Haikou "Harmonious Home" commercial and residential building is located at No. 47, Wuzhishan Road, Haikou City. The construction area of this project: 59055 square meters, including 53100.56 square meters above ground and 5954.44 square meters of basement building area. The total height of the project building: 94.68 meters. The basement of this project is integrated, and the ground is divided into 3 units. Among them, the above-ground structure of unit 1 is an independent tower, the above-ground 1~3 floors of units 2 and 3 are integrated with the podium, and the above 4 floors are divided into 2 towers.

The project is a prefabricated steel structure, the columns and beams are all prefabricated steel components, the floor is a steel truss floor deck, and the steel structure assembly rate reaches 50%.

The aboveground part of a unit covers an area of 18205.74㎡, and the total number of building floors: 27 floors, of which the underground 1 floor is a civil air defense layer with a height of 6 meters, the ground floor is an overhead floor with a height of 5.85 meters, and the above ground 2-27 floors are towers with a floor height of 3.00 ~4.89 meters; the above-ground building area of the second and third units: 34894.82 square meters; the total number of building floors: 26 floors, including 1 underground, 6 meters high, 1 to 3 floors above the ground for commercial, 6.00 meters/4.5 meters , 4~26 floors above ground, 3~4.89 meters high.

The project is located in the downtown area of Meilan District, Haikou City. The construction site is small and the access of materials and vehicles is time-limited. At the same time, there are commercial and residential buildings and military compound nearby. Working hours are very limited, from 7:00 to 12:00 in the morning. , 14:30-22:00 in the afternoon, the project department and team overcame numerous difficulties, raised personnel and machinery and equipment, and actively cooperated with the owner’s requirements for the construction period. During this limited time, the company worked overtime and actively coordinated the supply of materials. , Which truly embodies the service concept of "Zhongchen Steel Structure, Building Zhongchen".

Today, with the increasing development of green buildings, people are paying more and more attention to the methods of achieving green buildings. Comply with the development trend of green, ecological, healthy and comfortable building materials, and lead the development of building energy saving, green building materials, energy saving, material saving, water saving equipment, and the latest frontier of green building technology development. Prefabricated buildings are typical representatives of green buildings and their main advantages Including improving quality, improving efficiency and reducing labor. As a new industry actively promoted by the country, prefabricated construction will lead the future development direction of the construction industry.

...

Project name: Harmony Home Business Building A Steel Structure Project

Project Manager: Yu Yue Designer: Cheng Rongqin

Pre-settlement Clerk: Cui Zhusheng Quality Security Officer: Chen Xiangchao

Worker: Li Lirong Team: Chen Xiangchao's team

2020-06-08 14:52

MORE

Lin's Wood Industry Smart Dispatching Center (South China) Project Phase I

The first phase of Lin's Wood Smart Dispatching Center (South China) project is the first time that Lin's Wood Group has built a logistics and storage park in South China, with a total area of 250,000 square meters. This project is located in Huangji Village, Jiujiang Town, Nanhai District, Foshan City. It is mainly a portal type light steel frame structure. The main body is a single-layer steel structure. The wall and roof systems (including thermal insulation cotton), daylighting panels and canopy and other building systems are all For the production and installation of components, the roof adopts siphon drainage. The first phase has a construction area of 73561.53 square meters, a maximum span of 24 meters, and a building height of 15.5 meters.

The construction of the project started on July 16, 2017 and was completed in October 2017. It lasted 99 days. Due to the tight schedule, many construction procedures were not completed in the early stage of the main steel structure construction, resulting in simultaneous construction procedures and There are many construction units. A series of pile foundations, earth backfilling, concrete pre-burying and pouring, steel structure main body hoisting and maintenance installation, fire-fighting pipelines, water supply and drainage, water and electricity installation, ground concrete pouring, shelf installation, etc. The streamlined operation scene of the construction unit at the same time has brought great construction difficulties to our steel structure installation, especially the secondary transfer of materials and the delivery of the construction work surface. In order to hand over to Party A for use as soon as possible in accordance with the contract period, each process is completed in advance, and aluminum windows and sliding doors are installed at the same time as the steel structure wall panels are installed. During the construction process, it experienced continuous high temperature weather and four typhoons. Every day, workers suffered minor heat stroke. The project department took a series of measures such as taking turns to rest and preventing heatstroke to ensure the installation progress. Before the arrival of each typhoon, all the installation workers were evacuated to nearby hotels and other unfavorable conditions. With the joint efforts of the company and the project department, the contract construction period was completed on time and in quality. No safety and quality accidents occurred during the construction process. Therefore, it has been highly praised and recognized by the civil engineering and the owner. The owner also handed over the 120,000 square meter steel structure project of the second phase project to Zhongchen Company for construction.

Project Name: Lin's Wood Industry Smart Dispatching Center (South China) Project Phase I

Project Manager: Fan Preliminary Designer: Yang Chunqiang

Pre-settlement Clerk: Chen Liren Construction Supervisor: Cheng Fangde

Quality Security Officer: Chen Qiji Class Group: Liu Jianhua, Mo Bingrong

2020-06-08 15:18

MORE

Mona Lisa Wuzhou Base Phase I Project

The Wuzhou base of Guangxi Mona Lisa New Materials Co., Ltd. is currently the third production base of Mona Lisa Group in China, aiming to build a benchmark demonstration ceramic production base in China. Among them, the main forming workshop is the most important production workshop in the Wuzhou base. The building area is 86394 square meters, the building height is 17.7 meters, the maximum span of a single span is 33 meters, and the main steel structure consumption is 2500 tons.

This project company is undertaken as a general contracting project, including plant foundation, main steel structure, electrical room, office foundation and all decoration works in the plant, drainage engineering in the plant, and all equipment foundation engineering in the plant. It is not a small challenge for the company and the project department.

Since the first pile was laid in March 2019, the construction of the project site has been in full swing, and everything is carried out with the highest standards. Even in the face of abundant rainfall in spring and summer, there are 153 days in April and August, of which 97 days are rainy. Rainy days accounted for 63% of the total days, which seriously affected the construction progress. The project department and the team brainstormed, adapted measures to local conditions, combined with the actual situation of the site, and came up with construction measures one after another to ensure the realization of the schedule. For example, the rational use of night shift construction time, the flow of work arrangements for process teams, and the use of concentrated firepower to attack one by one. At the same time, in the actual construction process, especially in the civil engineering part, the owner continues to increase the amount of work due to equipment installation and process requirements, which is far beyond the scope of the contract. As the biggest strong backing, the company has continued to provide manpower, material and financial support to the project department. , Promote the operation of the project to the greatest extent and meet the requirements of the owners. In the end, it was smoothly guaranteed that the owner would start production in December. So far, we have worked with the owner to build a production base that meets high standards, high quality and world-class levels, which is actually the "Zhongchen Speed" of Mona Lisa.

Project name: Mona Lisa Wuzhou Base Phase I Project

Project Director: Huang Feiwang Deputy Project Manager: Yu Yue Designer: Liang Mingsheng

Pre-settlement staff: Cui Zhusheng Construction staff: Li Lirong, He Ziyong Quality security staff: Tang Wenyan

Class Group: Chen Xiangchao, Liang Nenghuo, Mo Bingrong, Chen Jianping, Xia Shuguang

2020-06-08 14:36

MORE

Plant III and Plant IV of Heshan Hongna Shoe Material Co., Ltd.

The third and fourth workshops of Heshan Hongna Shoe Material Co., Ltd. are located in Gonghe Industrial Zone, Heshan City, Jiangmen. The total construction area is 47611.33㎡, of which the third workshop is 2,3514.4㎡ and the fourth workshop is 2409.93㎡. The periphery of a single factory building is 160m long, 72m wide (partially 76m), 8.1m high, and 21.6m total height. The structural form is composed of a reinforced concrete frame main body and a steel structure roof. The two workshops are designed with the image of "convex" and are arranged in symmetrical mirror images. There are two connecting corridors in the middle.

The exterior of the factory building is maintained with a masonry structure, the inside is sprayed with latex paint, and the outside is covered with decorative bricks; the roof is equipped with an insulation layer, an air floor and a steel color floor, and the inside of the factory is equipped with fire compartments, air wells, and freight elevators. There are a total of 4 rows of windows on the facade of the factory building, and each row of windows is provided with a long window line above and below, which makes the building lines beautiful and more three-dimensional. In addition, there are parapet walls around the periphery of the factory building to make the building wind-resistant Capability and durability are guaranteed and the appearance is generous and decent.

This project is the company’s first civil engineering project, and higher requirements have been placed on the project department. In the same period of construction, although our bidding section is late, it is through the reasonable arrangement of the project department and the joint efforts of the team. Not only the construction period was completed on time, but the quality was also highly recognized by the owner.

Project Name: Plant III and Plant IV Project of Heshan Hongna Shoes Material Co., Ltd.

Project Manager: Xu Deliang Designer: Liang Mingsheng

Pre-settlement officer: Cui Zhusheng Quality security officer: Lin Xiaojia

Class group: concrete worker Liu Qin, iron worker Gan Xinzhong, wood worker Luo Yuquan, painter Chen Lei, Liu Xiubin, exterior wall paving worker Wu Yongzhao, shelf worker Lin Junyou, masonry Xiao lengthening, steel structure beam energy fire

2020-06-08 14:42

MORE

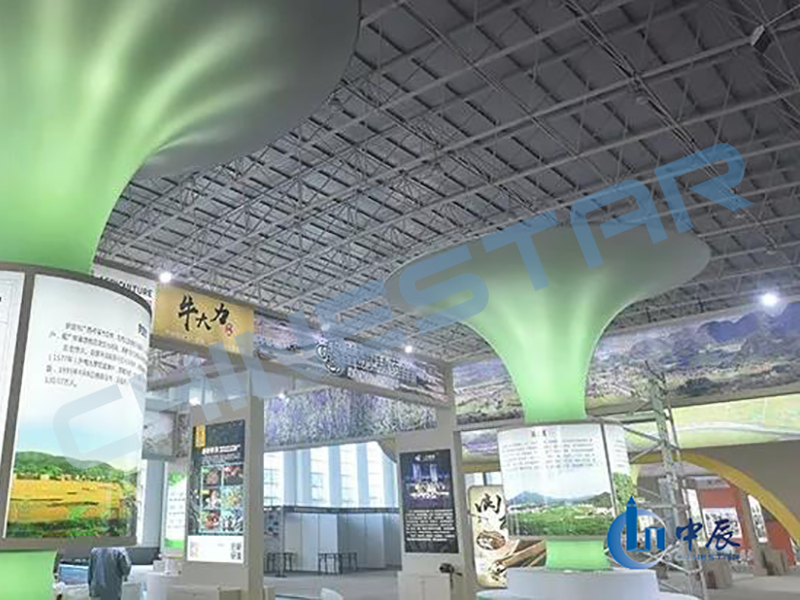

Guangdong Yunfu (Luoding) Agricultural Products Trade Expo Center

Guangdong Yunfu (Luoding) Agricultural Products Trade Expo Center is a new landmark building in Luoding City, with a building area of 15,400 square meters. The main structure is steel structure, the roof structure is a space grid structure, and the facade is a curved glass curtain wall. Integrate design and construction.

The project requires a construction period of only 45 days, including steel structure, grid, curtain wall cutting, procurement and construction. The construction period is short, which brings great challenges to material procurement and on-site installation. Through squatting in the factory to urge the materials, rationally split the project work surface, arrange 7 teams into two shifts to carry out the construction at the same time, the peak operator reaches 320 people, and there are more than 20 truck cranes and climbing trucks. An excellent team of "want to work, capable, and successful" sticks to the front line of the site, works hard, and organizes scientifically. It took 45 days to successfully complete the project construction task as scheduled. From October 17th to 24th, 2019, the Guangdong Nanyao Expo and Luoding Rice Festival Exhibition were held as scheduled, and the project construction was highly praised by Secretary Huang of Yunfu City, Guangdong Province for creating Yunfu speed.

Project name: Guangdong Yunfu (Luoding) Agricultural Products Trade Expo Center

Project Director: Pan Longbao Deputy Project Manager: Long Zhengbin Designer: Yang Chunqiang

Pre-settlement clerk: Cui Zhusheng Quality security officer: He Zengdao

Class team: steel structure, grid frame, roof team: Xiang Yifu, curtain wall and aluminum plate decoration team: Shenzhen Zhenheng Decoration Design Engineering Co., Ltd., Sichuan Lin Chenrui Decoration Engineering Co., Ltd.,

Wall team: Chen Xiangchao, Chen Jianping, Liang Nenghuo,

Fire retardant coating team: Zhongshan Sangong

2020-06-08 14:51

MORE

Pre

1

Next

WeChat public account